Gas springs are essential in many applications, providing controlled motion and force in various devices. When it comes to outdoor use, the need for weather-resistant gas springs becomes crucial due to exposure to harsh environmental conditions. This article explores the key aspects of weather-resistant gas springs, their benefits, applications, and the technological advancements that enhance their performance.

How Do Weather-Resistant Gas Springs Differ from Traditional Ones?

Weather-resistant gas springs differ from traditional gas springs primarily in their ability to withstand harsh environmental conditions, making them suitable for outdoor applications. Here are the key differences:

Material and Coating

Weather-Resistant Gas Springs: These are often made from stainless steel or coated with corrosion-resistant materials to prevent rust and degradation when exposed to moisture, salt, and other environmental factors.

Traditional Gas Springs: Typically constructed from standard steel, which may not have the same level of corrosion resistance, making them less suitable for outdoor use unless specially treated.

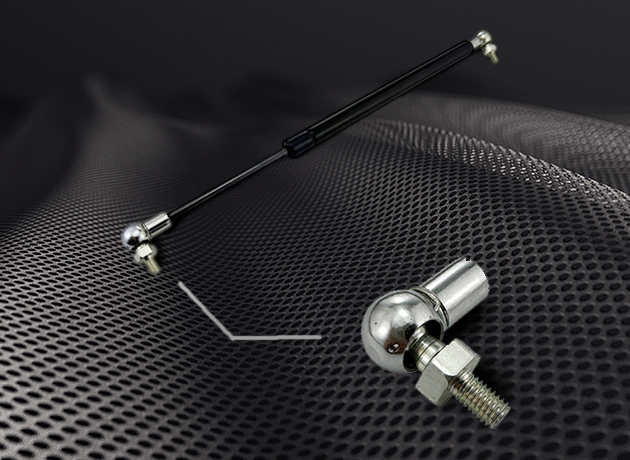

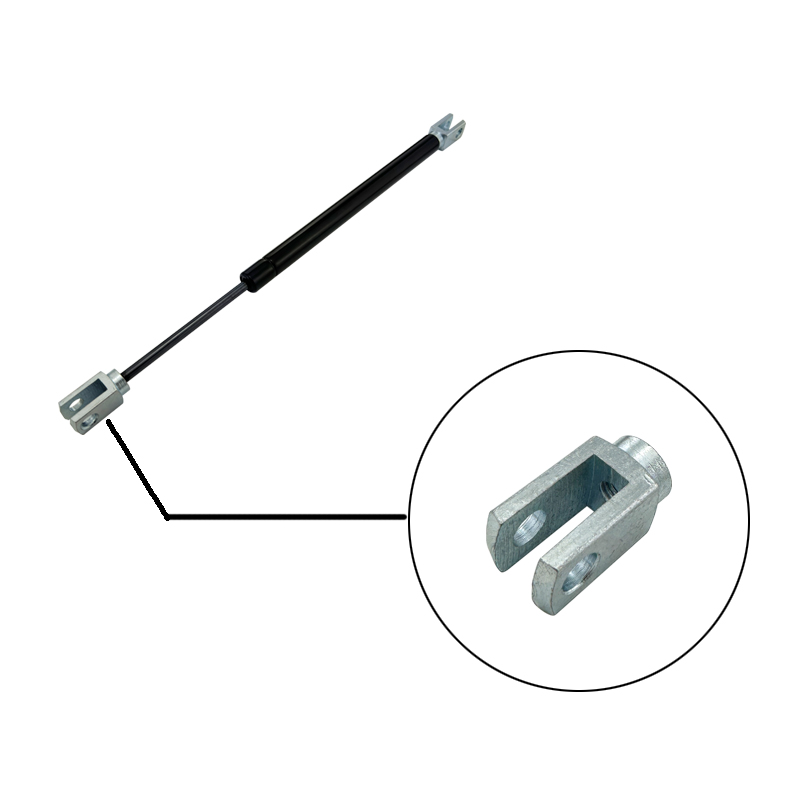

In particular, marine-grade stainless steel gas springs are commonly used in maritime applications, offering superior resistance to salt spray and oxidation. Manufacturers may also apply zinc plating, epoxy powder coatings, or nitride treatments to enhance surface hardness and rust protection.

Sealing and Protection

Weather-Resistant Gas Springs: They feature enhanced sealing technologies to prevent the ingress of water, dust, and other contaminants. This ensures the internal components remain protected, maintaining performance and extending the lifespan.

Traditional Gas Springs: While they have basic seals to maintain internal pressure, they might not offer the same level of protection against environmental elements.

In modern outdoor gas spring designs, multi-lip seals and dust caps are incorporated to guard against particulate contamination, a key concern in agricultural or construction environments.

Temperature Tolerance

Weather-Resistant Gas Springs: Designed to operate effectively across a wider range of temperatures, ensuring consistent performance in both hot and cold climates.

Traditional Gas Springs: Although they can function in variable temperatures, they may not be optimized for extreme conditions without additional modifications.

Temperature tolerance makes temperature-resistant gas springs ideal for outdoor installations in regions with seasonal fluctuations, such as cold-storage truck compartments or desert equipment.

Applications

Weather-Resistant Gas Springs: Commonly used in marine environments, agricultural machinery, and outdoor equipment where exposure to the elements is a concern.

Traditional Gas Springs: More often found in indoor applications or environments where exposure to harsh weather is minimal.

Durability and Maintenance

Weather-Resistant Gas Springs: Require minimal maintenance due to their robust construction and protective features, which help them withstand frequent use in challenging conditions.

Traditional Gas Springs: May require more frequent maintenance if used in environments they are not designed for, as exposure can lead to faster wear and tear.

Manywell Equipment Gas Springs for Vehicle Medical Semiconductor

Benefits of Using Gas Springs Outdoors

Gas springs offer several advantages over traditional mechanical springs, particularly in outdoor settings:

Minimal Maintenance: Due to their sealed design, gas springs require less maintenance compared to other types of springs that might need regular lubrication or cleaning.

Durability: The use of high-quality materials and coatings ensures that these springs can withstand the rigors of outdoor environments, offering a longer lifespan.

Smooth Operation: Gas springs provide smooth and controlled motion, which is beneficial for applications requiring precise movement control under varying loads.

Additionally, many weather-resistant gas spring solutions are customizable, allowing users to specify extension force, stroke length, and mounting style for different environmental conditions.

Applications of Weather-Resistant Gas Springs

Weather-resistant gas springs are versatile and find applications across various industries:

Automotive: Used in vehicle hoods, trunk lids, and tailgates to provide smooth opening and closing mechanisms.

Marine: Essential for equipment on boats and ships where exposure to saltwater is a concern.

Agriculture: Used in machinery that operates outdoors, providing reliable performance despite exposure to dust and moisture.

Construction: Employed in heavy machinery and equipment where durability against environmental factors is critical.

Solar Equipment: Outdoor gas struts support adjustable solar panels, allowing secure positioning under wind and weather variations.

Outdoor Cabinets and Enclosures: Provide safe and easy access to outdoor electrical boxes, tool chests, or gas-powered generators.

With the demand for weatherproof motion control systems growing, gas springs are increasingly found in smart infrastructure, RVs, mobile kiosks, and other outdoor innovations.

Technological Advancements in Weather-Resistant Gas Springs

Technological progress continues to enhance the capabilities of outdoor gas struts:

Self-lubricating pistons: Reduce friction and wear over time.

Adjustable force gas springs: Allow on-site fine-tuning of pressure to suit changing load requirements.

UV-resistant seals: Ensure longevity when exposed to sunlight for prolonged periods.

Locking gas springs: Provide secure holding capabilities, ideal for safety-critical outdoor applications.

Manufacturers now offer custom-engineered weather-resistant gas spring assemblies tailored to OEM specifications, improving efficiency and safety for outdoor machinery.

Conclusion

Weather-resistant gas springs are indispensable for outdoor applications due to their durability, low maintenance requirements, and ability to operate under harsh conditions. With continuous advancements in materials and technology, these components are becoming even more reliable and efficient. Whether used in automotive, marine, or industrial applications, weather-resistant gas springs provide a robust solution for motion control needs in challenging environments.

If you're looking for high-performance corrosion-resistant gas spring solutions for outdoor use, be sure to consult with a professional supplier. Whether you need custom gas springs for specific applications or are searching for gas springs to enhance operational efficiency and safety, Manywell provides solutions across industries with a range of sizes, capacities, and configurations to suit your needs. Browse the Manywell Equipment Gas Springs Collection for more details.