When it comes to industrial applications, selecting the right equipment handles is critical for ensuring efficiency, safety, and long-term durability. Whether you're working in the medical, semiconductor, automation, or any other sector requiring heavy-duty equipment, the importance of choosing the right industrial machine handles cannot be overstated. Here we will explore the various factors to consider when choosing heavy-load handles, the types of handles available, and why ergonomic and customizable designs can make a significant difference in your operations.

What Are Heavy-load Handles?

Heavy-load handles are specialized tools designed to aid the movement and control of industrial machinery and equipment. They provide a secure grip, making it easier for operators to handle equipment under challenging conditions. These handles are especially crucial in industries where machinery is large, heavy, or used in environments that demand reliability and safety.

Due to their widespread use, many manufacturers, including Manywell, offer a variety of equipment handles that cater to different needs. These handles come in various materials, designs, and sizes to suit specific applications, ensuring the equipment remains functional and safe for all users.

Why Choose the Right Industrial Machine Handles?

Industrial machine handles are not just functional—they are integral to ensuring the safety and performance of machinery. Some of the key reasons to select the right handles are:

Safety and Control: Properly designed handles reduce the risk of accidents by providing a firm grip, preventing slippage during operations.

Ergonomics and User Comfort: Ergonomic handles, such as those designed to reduce hand fatigue, ensure that operators can use equipment for extended periods without discomfort.

Durability and Weather Resistance: Industrial equipment often operates in harsh conditions—extreme temperatures, moisture, or chemicals. Heavy-duty handles designed for outdoor use must be able to withstand these conditions without degrading, which is why weatherproof or corrosion-resistant materials are often necessary.

Heavy-load Handles for Industrial Use

Types of Heavy-load Handles

When choosing equipment handles, it’s essential to consider the type of machinery you’re working with. Here are the most common types of heavy-load handles available:

Stainless Steel Machine Handles

Stainless steel is a popular material for industrial machine handles due to its durability, corrosion resistance, and clean appearance. Stainless steel handles are ideal for industries like medical equipment manufacturing, where hygiene and durability are key considerations. Their sleek design is easy to clean and maintain, making them perfect for environments that require frequent sanitation.

Ergonomic Handles for Tools

An ergonomic handle design helps reduce operator fatigue, especially in industries that involve prolonged use of machinery. Ergonomically designed handles are specifically crafted to fit comfortably in the hand, minimizing stress on the wrist and fingers.

Non-slip Handles for Wet Conditions

In certain industrial settings, such as food processing or medical labs, wet conditions can increase the risk of slippage. Non-slip handles are designed to maintain grip even in such conditions. These handles usually feature textured surfaces or rubber grips that offer a secure hold, reducing the risk of accidents when working with wet or slippery equipment.

Customizable Equipment Handles

For industries with specific needs or custom equipment, customizable equipment handles can be a game-changer. Manywell, for instance, provides a wide range of adjustable and customizable handles to suit different applications. Customization options include varying the material, design, size, and color to meet both aesthetic and functional requirements.

Weatherproof Handles for Outdoor Equipment

For outdoor equipment that must endure extreme weather conditions, weatherproof handles are a must. These handles are designed to resist rust, corrosion, and UV damage, making them ideal for industries like aviation, marine, and energy, where equipment is often exposed to the elements. These handles ensure that equipment remains functional and safe, regardless of the weather.

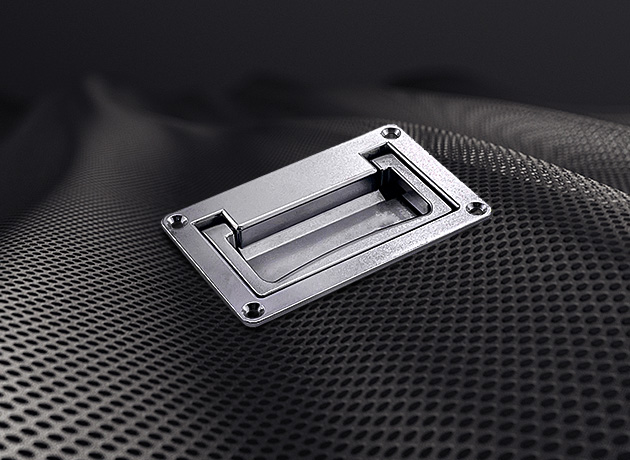

Heavy-duty Handles for High-strength Applications

Some industries, such as heavy machinery or transportation, require high-strength handles capable of withstanding immense pressure. These handles are built with tough, durable materials, such as reinforced plastics, aluminum, or steel, to bear heavy loads without compromising safety.

Lockable Handles and Security Features

Some industrial applications may require additional security features to protect sensitive equipment. Lockable handles and magnetic locks provide extra safety by preventing unauthorized access. Whether it's a toggle latch, mortise lock, or thumb latch, these handles ensure that your machinery remains secure while being easily operable by authorized personnel.

High-strength Handles for Heavy Loads

How to Choose the Right Equipment Handle?

Choosing the right handle for your industrial machinery involves considering several key factors:

Application and Industry Requirements: Consider what kind of equipment you are working with. Will the handle be exposed to heavy loads? Will it need to withstand extreme conditions like moisture or high temperatures? For instance, stainless steel machine handles are ideal for medical and food industries, while weatherproof handles are better for machinery used outdoors.

Ergonomics and Comfort: Ensure that the handles are designed with ergonomics in mind, especially if workers will be using the equipment frequently. Ergonomic handles for tools can help reduce fatigue, making them ideal for environments where employees handle equipment all day long.

Customization Needs: If your machinery requires specialized handles, look for customizable equipment handles that can be tailored to suit your specific needs. From custom colors to unique sizes and materials, the right customizable handle will ensure your equipment is as functional as it is efficient.

Durability and Maintenance: Equipment handles should be designed to withstand wear and tear. Look for handles that are easy to clean and can stand up to prolonged use. Durable handles for outdoor use are also an important consideration if your equipment operates in harsh environments.

Load Capacity: Always consider the load-bearing capacity of the handles you select. High-strength handles for heavy loads are crucial when dealing with large or industrial machinery, ensuring that your equipment can be operated safely and securely.

Conclusion

Choosing the right heavy-load handles for your industrial applications is a crucial decision that can affect the safety, comfort, and performance of your equipment. From ergonomic handles for tools to weatherproof handles for outdoor equipment, the right handles are designed to meet the unique demands of your industry.

Elevate your equipment's performance, safety, and user experience with Manywell's exceptional range of equipment handles. Whether you need customizable equipment handles or non-slip handles for wet conditions, the right solution is just a selection away. Browse our high-quality equipment handle selection to find the right handle for your equipment needs.